Technical problems are not to blame for the failure of tire serial number scans to get recorded. The primary reason is because the criteria used for scanning do not correlate to the true physical movement of the tire during the operational process.

When scanning cardboard boxes or retail products, we expect consistency in time at which the products will be scanned. However, when we scan tires there is no such predictability because tires will be scanned at various times during the process from off-loading to stacking, to redistribution, to returns, and even to scrapping. Additionally, if we look at how the serial number is printed, it may be stamped into the tire, wrapped around a curved sidewall, or worn after it has been scanned from inside the tire. All these factors make the decision of using mobile scanners or a fixed camera system a much more strategic decision than may first appear.

In order to build a solid and reliable tire traceability system, we must first understand how the two different approaches perform in the real world.

How Tire Serial Number Scanning Really Works

People have a tendency to think of scanning as the scanning of flat labels or printed codes. This is evidenced by the large number of search requests related to how to scan a barcode, how to scan a barcode using an iPhone, etc. However, tire serial number scanning has a very different set of realities.

Rather than reading high contrast printed bars, systems need to actually interpret low contrast embossed characters on rubber. When reading a barcode with a camera, it is necessary for the camera to compensate for the curvature of the tire, shadows that cover part of the barcode, dirt on the barcode, and the inconsistent lighting conditions. Many generic barcode solutions fail at this critical point.

The mobile scanner and fixed camera systems were both designed to resolve this issue but utilize completely different techniques to do so.

Mobile Scanners in Tire Operations

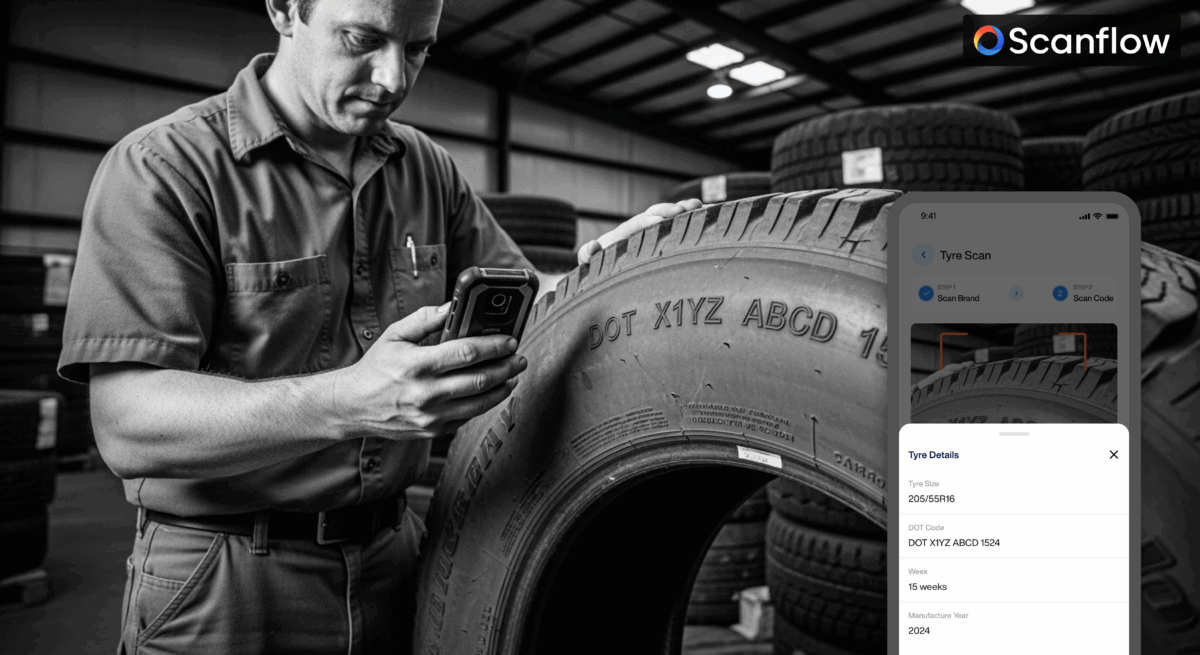

Mobile Scanners Generally Operate Using a Smart Phone or Rugged Hand-held Device Which Runs a Mobile Scanner Application. The Camera on These Devices Utilizes the Camera to Capture an Image of aTire’s Side Wall to Provide a Software Program with the Information It Needs to Extract the Tire’s Serial Number.

The need to use mobile scanners in tire workflows is significant because tires are not usually in a controlled position. Mobile scanners are used by warehouse staff members for barcode scanning in receiving and dispatching deliveries of tires. Retailers utilize mobile barcode scanning equipment for performing inbound inspections and validating warranties. The teams performing scrap and recycling activities also use mobile bar-code scanners because of dramatic differences in orientation and condition of tires.

Mobile scanners for tire applications are generally not the same as consumer grade tools used for packaging retail items. Mobile scanners are adapted to handle distorted angles and damaged surfaces. That is why many simple mobile barcode scanner applications do not provide acceptable results without being backed by advanced visual intelligence.

Strengths and Limitations of Mobile Scanning

The major strength of mobile scanning is the ability of a mobile scanner to go to the tire, versus having to move the tire to a mobile scanner for scanning the barcode, which make it an ideal application for tire aftermarket distribution and reverse logistics.

However, mobile scanning also requires the user to be trained. Factors such as angle, distance and stability in scanning will affect the quality of results. If no intelligent guidance and validation are provided during scanning operations, the chances for increased error rates will increase.

The information technology known as throughput is limited in that mobile scanning is only capable of working with one tire at a time; therefore mobile scanning will not work on high speed production lines.

A case can be made for mobile scanning flexibility instead of moving large quantities of items.

Fixed Camera Systems for Tire Serial Number Scanning

Fixed camera systems have been designed differently than mobile scanners. The cameras are mounted at set points along the conveyor or inspection(s), where they can be placed in a predictable place along the path(s) of the tires as they pass.

In a well-controlled manufacturing environment, fixed cameras can run flawlessly. Having known light levels, directions and consistent motion will give the camera the ability to take a scanned picture of the serial number continuously and at speed. In fact, many operations will first purchase barcode scanners to establish points on a PC camera for future set-up to create a stable location when converting to industrial cameras.

Fixed cameras are ideal for production lines as they can eliminate personnel variability and provide a very high throughput.

Where Fixed Camera Systems Fall Short

The main advantage of fixed systems (consistency) also is the main disadvantage of fixed systems. In many instances printing on a tire will be out of orientation – meaning that the serial number printed on the tire may have rotated away from the fixed position to which it was installed.

When a tire rotates unexpectedly, if the serial number rotates and is facing inward or if a tire has a piece of debris on the side wall, the fixed camera will not see the printed serial number. In addition, unlike a mobile scanner app, the fixed camera cannot reposition (i.e., not adjust angle or height to try and scan the first time missed) to get another chance to see the printed serial number on the side wall due to having no other places to mount an additional camera.

The costs associated with this technology will rise quickly due to the costs of equipment to install, calibrate, control the lighting of and maintain a stationary system. As such, stationary systems are not widely deployed in places like warehouses, retail stores, and scrap yards where control zones are not available.

The “Hidden Camera Scanner” Misconception

When searching for a hidden camera scanner, users often display their frustration over not finding an actual solution. There is no type of hidden or passive system that can accurately scan a tire serial number unless there is a clear line of vision to that serial number.

While you can use a fixed or mobile scanner to acquire a usable image of the serial number, the difference is not invisibility but rather the adaptability of either system.

How Tire Businesses Actually Scan in Practice

In a typical real-world operation, most businesses do not use just one method of scanning.

Manufacturing will primarily rely on stationary cameras for their speed of scanning. Warehousing and retail will primarily rely on their flexibility through mobile workflows that utilize barcode scanners. Exceptions, audits, and failures will be scanned with mobile scanners inside of manufacturing facilities.

The Hybrid Reality Is Present Regardless of Intent.

So, What’s the Conclusion?

There is no right answer for everyone.

Mobile scanning excels at tracking tires in areas of unpredictability. Fixed camera systems perform well in controlled environments. The highest risk occurs when a traceability system is designed, assuming everything will operate perfectly.

The best strategies for tire serial number scanning are based on coverage rather than the hardware used. Each scanning method provides a back-up to other methods of scanning and ensures that each type of scanned serial number maintains the same level of traceability.

This is how scanning systems differ from traceability systems.