In the complex world of tire recycling and waste management, accurate data collection and traceability have become critical challenges for tire recyclers and scrap tire handlers. The Department of Transportation (DOT) and Tire Identification Number (TIN) codes printed on tire sidewalls contain a wealth of information that, when properly captured and processed, can enhance the industry’s approach to compliance, reporting, and operational efficiency.

Understanding DOT/TIN data: The foundation of tire traceability

Every tire manufactured for highway use carries a DOT code that serves as its unique fingerprint. This alphanumeric sequence contains crucial information, including the manufacturer’s plant code, tire size, brand code, and most importantly, the production date. For tire scrapers and recycling facilities, this data represents far more than simple identification; it’s the key to comprehensive scrap tire traceability and regulatory compliance.

The TIN portion of the DOT code identifies explicitly the date and place of manufacture, enabling precise tracking throughout its lifecycle. This information becomes invaluable when preparing manifests, meeting state regulatory requirements, and maintaining accurate inventory records for tire disposal operations.

The challenge of manual data collection

Traditional methods of collecting tire data involve manual inspection and handwritten logs, a process that’s not only time-consuming but prone to significant errors. Tire recyclers often struggle with:

- Data entry errors that compromise manifest accuracy

- Inconsistent documentation across different operators

- Time-intensive processes that slow down operations

- Difficulty in maintaining structured tire data for reporting purposes

- Challenges in meeting state compliance requirements efficiently

These manual processes create bottlenecks in tire recycling operations, increasing the risk of regulatory non-compliance and potentially resulting in costly penalties and operational disruptions. The relief from these challenges is a significant benefit of AI tire scanning.

How AI scrap tire scanning transforms operations?

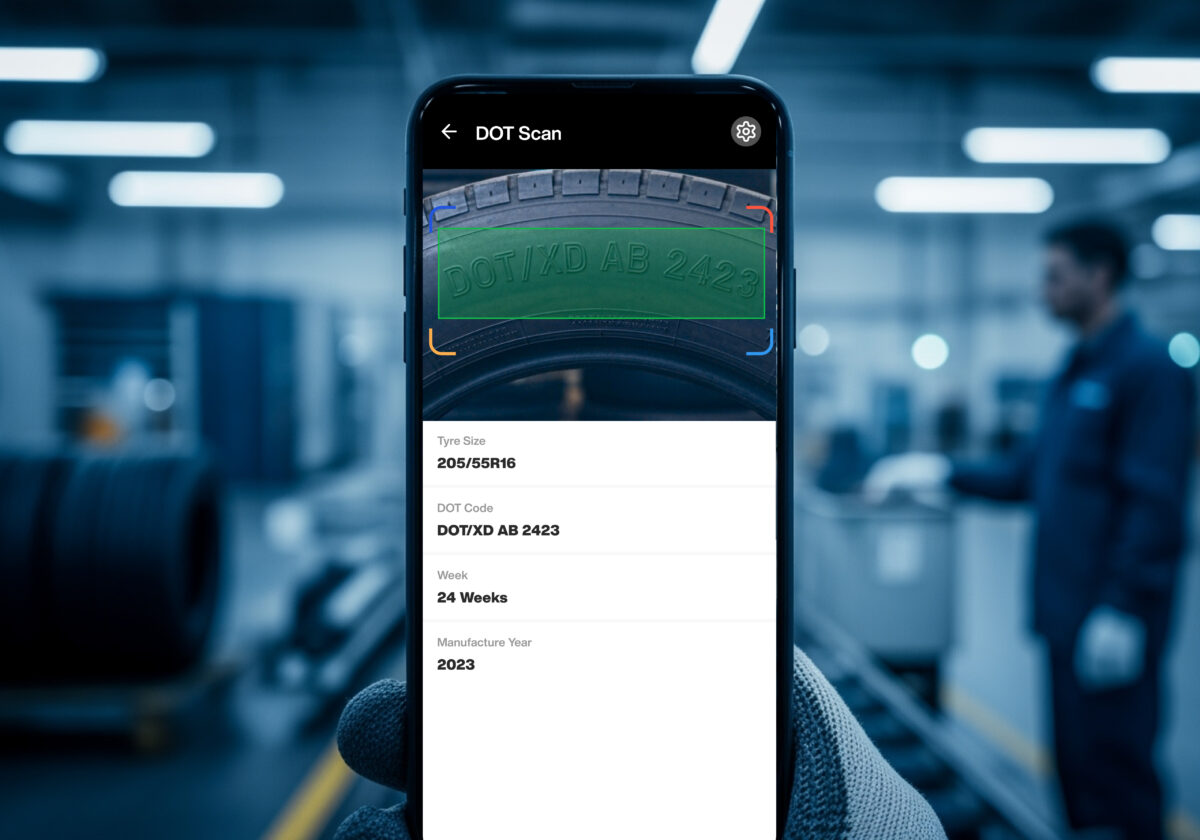

Modern AI scanners have emerged as a game-changer for the tire recycling industry. Tire sidewall scanning solutions leverage artificial intelligence to automatically capture, interpret, and process DOT/TIN data with unprecedented accuracy and speed, empowering industry professionals with more control and confidence.

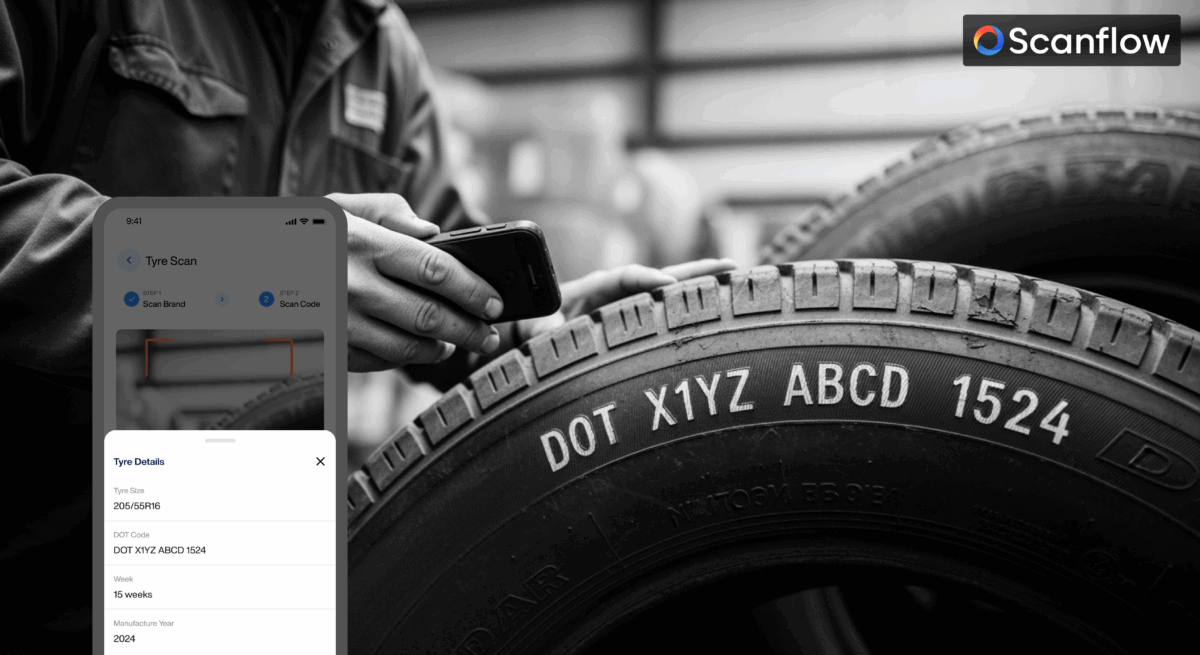

Scanflow’s Tire Sidewall SDK represents a breakthrough in automated tire identification, offering tire recyclers and scrapers a comprehensive solution that addresses the industry’s most pressing data collection challenges. The solution utilizes advanced computer vision for tires to:

Capture data with mobile flexibility

The solution works seamlessly with mobile applications and IP cameras, allowing operators to scan tire sidewalls using existing devices. This mobile tire scanning capability means facilities can implement the technology without significant infrastructure investments, making it accessible and convenient for operations of all sizes.

Integrate with existing systems

One of the key advantages of Scanflow’s approach is its ability to integrate with any backend system customers already have in place. This tire data management integration ensures that scanned information flows directly into existing workflows, eliminating data silos and maintaining operational continuity.

Deliver structured data and analytics

The Tire Sidewall scanning SDK automatically structures collected data into actionable insights through comprehensive dashboards. This capability provides real-time visibility into tire volumes, types, and processing status, enabling better decision-making and resource allocation.

Streamlining manifest preparation and compliance

The most significant benefit of automated tire scanning is its impact on manifest preparation. State regulations require detailed documentation of tire disposal activities, and manually preparing these documents is both time-consuming and error-prone.

With AI Tire Sidewall Scanning, manifest creation becomes automated mainly. The system captures all necessary tire specifications, including size, brand, and TIN/DOT codes, and formats this information in accordance with regulatory requirements. This digital tire tracking approach not only saves time but also significantly reduces the risk of compliance issues.

The future of tire recycling/scarp operations

As state regulations become increasingly stringent and the volume of scrap tires continues to rise, the need for efficient and accurate data collection becomes more critical. Tire scanning solutions not only improve operational efficiency and compliance but also represent a significant step towards more sustainable, environmentally friendly tire recycling operations.

The implementation of AI tire sidewall scanning offers immediate benefits in terms of operational efficiency and compliance, while also providing the foundation for advanced analytics and process optimization. Facilities that adopt these technologies position themselves to meet growing regulatory demands while maintaining competitive advantages through improved efficiency. This can lead to significant cost savings in terms of reduced manual labor, fewer compliance issues, and optimized resource allocation.

Conclusion: Embracing digital transformation in tire recycling

The integration of DOT/TIN data capture through advanced scrap tire scanning technology represents more than just an operational upgrade; it’s a fundamental shift toward data-driven tire recycling operations. By leveraging Scanflow’s Tire Sidewall SDK, tire recyclers and scrapers can transform their approach to compliance, reporting, and operational management.

As the industry continues to evolve, those who embrace intelligent tire scanning solutions will find themselves better positioned to navigate regulatory complexities, reduce operational costs, and build more sustainable business models. The future of tire recycling lies in accurate, automated data collection, and that future is available today.

Discover how Scanflow enables recyclers to capture DOT/TIN data with accuracy and speed.