Intelligent data capture

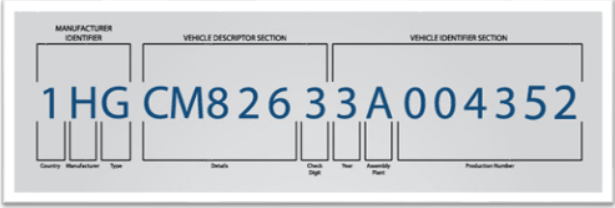

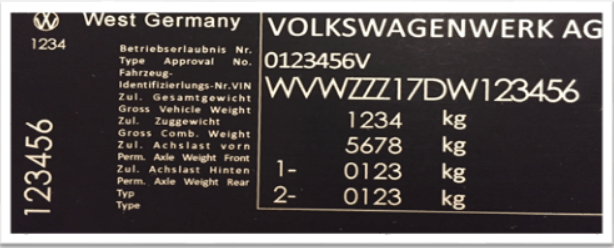

- Intelligent data capture (IDC) is a process of automatically extracting data from unstructured and semi-structured documents using artificial intelligence (AI) and machine learning (ML) technologies.

- IDC solutions can be used to capture and process data from a wide variety of documents, including invoices, purchase orders, contracts, medical records, and more. IDC solutions typically use a combination of OCR, NLP, and AI to extract data from documents.

- OCR is used to convert scanned images of documents into text. NLP is used to understand the meaning of the text and identify key data points. AI is used to learn from the data and improve the accuracy of the data extraction process over time.

Why is IDC important?

- Intelligent data capture (IDC) is important because it helps businesses to automate the data capture process, which can lead to significant efficiency gains, improved data quality, reduced costs, and enhanced compliance.

- IDC solutions can be used to capture and extract data from a wide variety of documents, including invoices, purchase orders, contracts, medical records, and more. This data can then be used to improve a variety of business processes, such as order fulfillment, customer service, and financial reporting.

- IDC solutions are also becoming increasingly important as businesses move to digitize their operations. By automating the data capture process, businesses can reduce their reliance on manual data entry, which can free up employees to focus on more strategic tasks. Overall, IDC is an important technology that can help businesses to improve their efficiency, productivity, and profitability.

Top 5 Intelligent Data Capture Solutions Companies in 2024

1) Data Capture Solutions

Data Capture Solutions (DCS) is a company that specializes in creating custom data capture systems. They offer a variety of hardware and software solutions, as well as services to support their customers throughout the data capture process. DCS partners with other companies to provide these solutions, ensuring that their clients have access to the latest and most effective technologies. Whether you need a simple system for capturing basic data or a complex system for handling large volumes of data, DCS can help you find the right solution for your needs.

2) Scanflow

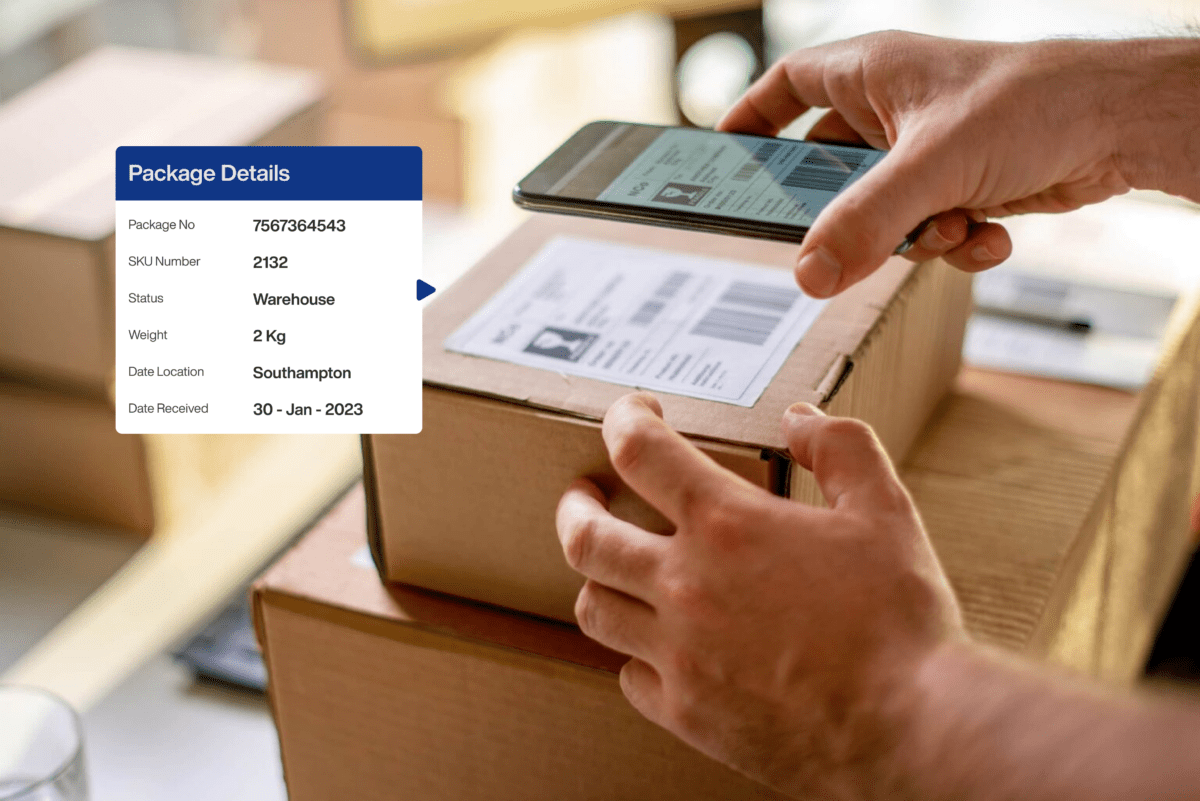

Scanflow is an innovative AI-powered data capture tool that leverages smart devices to scan and capture information. It’s adept at handling various tasks, from scanning text and barcodes to processing ID documents. Scanflow’s capabilities extend beyond mere data capture, as it can also automate workflows and streamline processes, ultimately enhancing efficiency. Imagine using Scanflow to track inventory in a warehouse or verify customer IDs at a retail store – these are just a few examples of its versatility.

Scanflow boasts numerous advantages, including increased accuracy, reduced costs, and improved efficiency. Its user-friendly interface and seamless integration with existing systems make it an attractive option for businesses seeking to optimize their data capture processes. So, if you’re looking for a powerful and versatile tool to elevate your data capture game, Scanflow is definitely worth considering.

3) Anyline

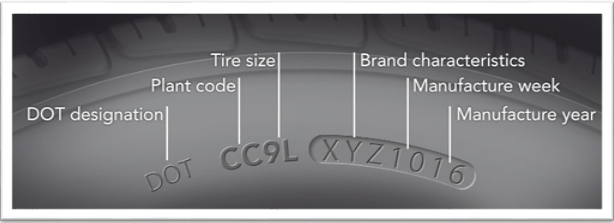

Anyline’s platform is designed to be easy to use, even for people who are not familiar with data capture technology. The platform uses computer vision and machine learning to automatically extract data from images, so there is no need for manual data entry. Anyline also offers a variety of SDKs and APIs that make it easy to integrate their platform into existing applications. One of the benefits of using Anyline is that it can be used with existing smartphones and tablets. This means that businesses do not need to purchase any new hardware in order to start using Anyline’s platform. Anyline also offers a variety of subscription plans that make it affordable for businesses of all sizes.

4) Scandit

Scandit specializes in mobile barcode scanning and smart data capture solutions. They empower businesses by transforming everyday smartphones and tablets into powerful data acquisition tools. Imagine capturing barcodes, text, ID documents, faces, and other visual data effortlessly, with lightning speed and high accuracy. This eliminates the need for bulky dedicated scanners and opens up a world of possibilities for streamlining workflows, boosting productivity, and enhancing customer experiences. From retail checkout and logistics to healthcare and field services, Scandit’s technology seamlessly integrates into existing apps and processes, delivering tangible value across diverse industries.

5) Dynamsoft

Dynamsoft is a company that specializes in data capture software. They offer a variety of products that can help businesses automate their data capture processes. Dynamsoft’s software is used by a wide range of organizations, from small businesses to large enterprises.

One of the benefits of using Dynamsoft’s data capture software is that it can save businesses time and money. By automating data capture, businesses can eliminate the need for manual data entry, which can be a slow and error-prone process. Dynamsoft’s software can also help businesses improve the accuracy of their data. By using optical character recognition (OCR) technology, Dynamsoft’s software can extract data from documents with a high degree of accuracy.