Automation has become a potential solution for manufacturing industries that helps them to enhance workflow processes and simplify procedures.

In the world of manufacturing, precision and efficiency are paramount. However, even large companies face challenges that require innovative solutions. One such challenge faced by a truck manufacturing company was the need to eliminate manual efforts in data extraction from diverse textual components.

Scanflow aims to automate the extraction of critical information from various sources, revolutionizing their manufacturing processes.

The Challenge of Manual Efforts

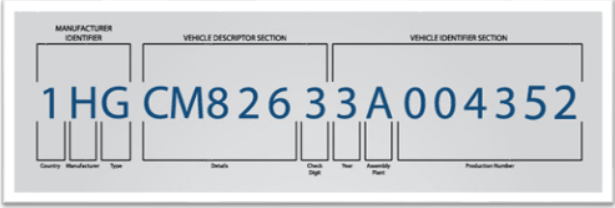

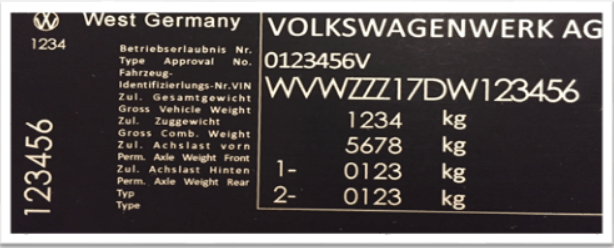

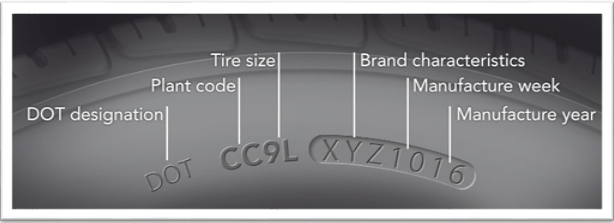

A leading truck manufacturing company faced challenges in their manufacturing processes and were characterized by manual data entry and verification procedures. These processes, while essential, were time-consuming, error-prone, and resource-intensive. The need to manually extract data from textual components, such as Vehicle Identification Numbers (VIN), VIN Plates, Air Tank Serial Numbers, Suspension Serial Numbers, and Tire Sidewalls, posed a significant challenge. It not only slowed down production but also increased the risk of errors.

A Vision for Automation

Recognizing the need for change, the truck manufacturing company embarked on a journey to harness the power of automation. To automate the identification of key phrases, named entities, and structured data in text, effectively eliminating manual efforts.

The objective of Scanflow was to extract accurate data, including VINs, Tire Identification Numbers (TIN), and Tire Numbers, from diverse textual components. This data was critical for quality checks and production management. The extraction process had to be highly accurate and reliable, ensuring that the data captured was error-free.

The extraction achieved over 97% accuracy in capturing component text was a key objective. This would significantly reduce the need for manual interventions. All captures had to function offline on edge devices, ensuring that the process was resilient to connectivity issues.

Integration for Seamless Operations

Scanflow integration with Manufacturing Execution Systems (MES) and SAP HANA systems extracted data needed to flow seamlessly into these systems to ensure accurate record-keeping and effective production management. MES provided real-time tracking and component history, while SAP HANA handled data analytics and insights for informed decision-making.

-

-

Use Cases: Delivering Precision and Quality

- Stencil & Air Tank Part Number Comparison: Ensuring that stencil part numbers and air tank part numbers matched in the assembly line and quality checks was crucial. This process not only confirmed the proper fitting of components but also prevented mismatches.

- VIN Number Mapping: Mapping each VIN with the corresponding database entry during assembly and quality checks ensured the correct components were used, enhancing accuracy and compliance.

-

-

- VIN Plate Mapping: Mapping VIN plate information with the database during cockpit assembly and quality checks guaranteed that specifications were met, contributing to precision.

-

- Tire Sidewall Capturing: Capturing tire sidewall details during assembly and quality checks ensured that the right tires with accurate specifications were installed, a vital element in vehicle safety and performance.

- Vision Intelligence: Utilizing CCTV footage for symbol comparison in air suspensions and vehicle cockpit images ensured swift intervention and quality control, further enhancing product reliability.

A New Era of Excellence

The successful implementation of Scanflow transformed the workflow operations. Manual efforts were drastically reduced, errors were controlled, and the speed of operations improved significantly. With seamless integration into MES and SAP HANA, data became an asset, driving efficiency and quick decision-making.

Through this, the truck company not only enhanced assembly precision but also streamlined quality checks, ensuring top-tier products with unparalleled reliability. By adopting Vision Intelligence and automation, they achieved a new era of manufacturing excellence, setting new standards in the automotive industry.

Leveraging manufacturing industries with innovative technologies like Scanflow will provide a significant competitive advantage. It showcases how automation, precision, and integration can lead to transformative results, positioning the company at the forefront of the automotive manufacturing industry. In recent years, many industries have started to adopt smart automated solutions in their workflows. This will mitigate operational costs and workers can have a productive work environment with errorless and more intelligible processes.