Low light, damaged labels, and rotated barcodes aren’t rare exceptions they’re part of the daily grind in logistics, retail, and warehousing. These conditions slow teams down and break most traditional scanning systems.

Scanflow AI Asset Identification is made for exactly these real-world challenges. Built for speed and accuracy, it consistently outperforms legacy scanners in fast-moving, high-volume environments where precision can’t wait.

1. Low-Light Scanning

Scanflow reads barcodes even in poorly lit warehouses, dim corners of storage units, or night-time field operations. It compensates for shadows, glare, and motion blur—making it ideal for mobile or fixed-camera use cases.

2. Damaged or Partially Obscured Labels

Where traditional scanners fail, Scanflow succeeds. It can interpret:

Torn or scratched barcodes

Smudged, faded, or dirty labels

Codes covered by plastic or partially blocked

This ensures high readability even during rugged use across supply chains.

3. Rotated and Misaligned Barcodes

Scanflow’s AI Asset Identification can decode barcodes regardless of their orientation sideways, upside down, or curved around surfaces. This flexibility eliminates the need to manually realign items for scanning, saving time and reducing errors.

Where Scanflow Stands Out

Scanflow is designed for environments where speed, accuracy, and tough conditions are the norm:

For logistics teams, it eliminates delays caused by unreadable barcodes on moving cartons and pallets.

For retail operations, it enables seamless shelf and POS scanning, regardless of packaging shape or label condition.

For delivery and warehouse workers, Scanflow acts as a top barcode scanner that performs even under poor lighting or inconsistent label placement.

It’s not just about reading codes it’s about improving throughput, reducing scan failures, and enabling automation at scale.

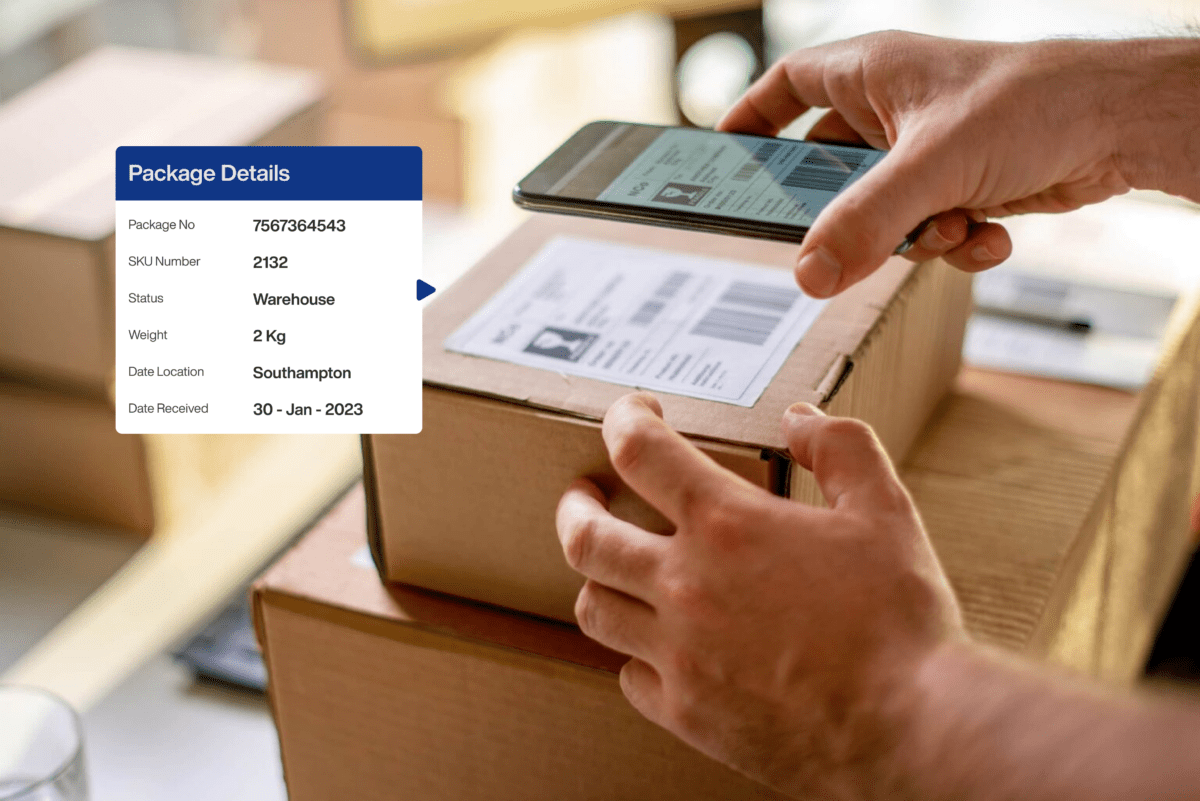

Mobile SDK for Seamless Integration

Scanflow offers a lightweight, developer-friendly Mobile SDK for iOS and Android that brings its AI barcode scanning capabilities directly to any mobile device. Whether integrated into your warehouse management app or a last-mile delivery workflow, the SDK ensures:

Fast, accurate scans using the device camera

Support for real-time processing under variable lighting

Robust performance on damaged, distorted, or rotated barcodes

Easy integration with minimal code and full documentation

With Scanflow’s SDK, you can turn any smartphone into an enterprise-grade AI scanner, drastically cutting hardware costs while scaling with ease.

Proven Results

Companies using Scanflow have reported:

Over 98% scan accuracy in poor conditions

30–50% faster processing speeds

Reduced scan retries and manual interventions

Better visibility and tracking across supply chain workflows

Ready to Experience the Difference?

Whether you’re modernizing warehouse processes, managing field logistics, or enhancing retail operations, Scanflow delivers the speed and reliability expected from a top AI barcode scanner.

Explore our capabilities or request a demo.