In today’s business landscape, the ability to optimize workflows is a key driver of success. From inventory management to customer interactions, streamlining operations can significantly impact a company’s bottom line. This is where Smart data capture solutions step in, offering a cutting-edge approach to enhancing efficiency across various industries.

The Evolution of Data Capture:

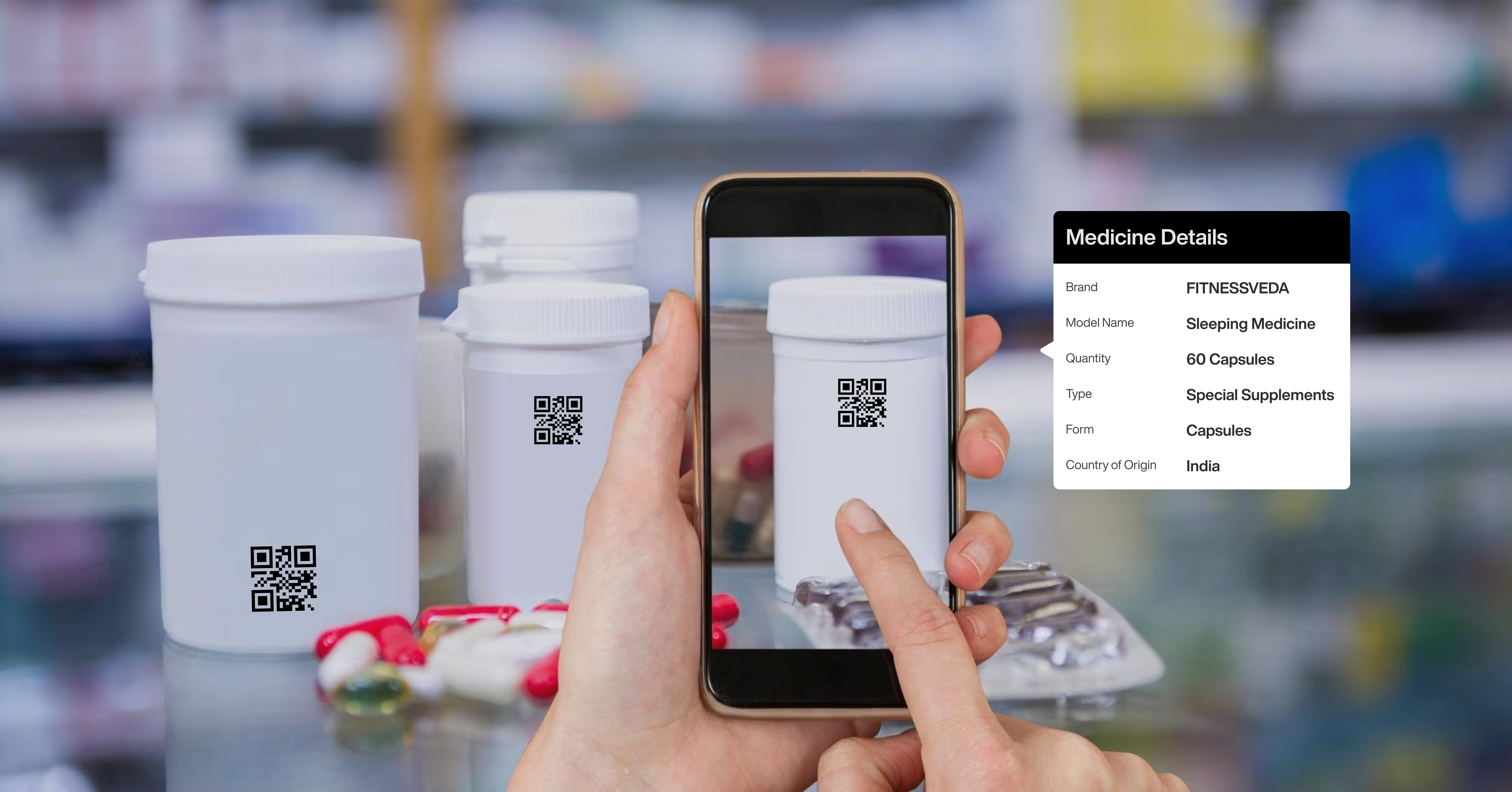

Gone are the days of manual data entry and cumbersome paperwork. Data capture has ushered in a new era with innovative technology that leverages the power of AI, machine learning, and computer vision. This transformation enables businesses to seamlessly collect, process, and utilize data from a multitude of sources, all with unparalleled speed and accuracy.

Revolutionizing Workflows:

Imagine a warehouse, where inventory management is no longer a daunting task. Scanflow’s data capture solutions empower businesses to effortlessly scan barcodes, QR codes, and text, transforming complex inventory processes into streamlined operations. This real-time data capture allows for swift stock checks, accurate product tracking, and efficient order fulfillment – ultimately translating into satisfied customers and increased revenue.

Tire manufacturing process

In the tire manufacturing sector, precision and speed are of the essence. Scanflow’s data capture solutions revolutionize the tire production process by accelerating crucial operations. From capturing tire specifications to quality control checks, this technology guarantees data accuracy, minimizes errors, and amplifies overall production safety. The result? More time dedicated to optimizing manufacturing processes and less time consumed by manual tasks, ultimately translating to a higher quality tire output.

Tire manufacturers can utilize Scanflow’s data capture to monitor inventory levels effectively. Automated tracking of raw materials and finished products ensures that production continues seamlessly without the risk of stockouts or overstock situations. This precise inventory management leads to cost savings and improved resource utilization.

Seamless Integration:

One of the standout features of Scanflow’s data capture solutions is their ability to seamlessly integrate into existing systems. This means that businesses don’t need to undergo a complete overhaul of their technology infrastructure to reap the benefits. Whether it’s integrating with inventory management software, customer relationship management platforms, or enterprise resource planning systems, Scanflow’s solutions enhance without disruption.

Empowering Workforce Mobility:

In a world where remote work and on-the-go operations are becoming the norm, Scanflow’s data capture solutions provide a seamless bridge between physical and digital spaces. With mobile devices equipped with Scanflow’s technology, employees can capture data from anywhere, eliminating the need for manual data entry and reducing the chances of errors that come with it.

Enhanced Decision-making:

Data capture isn’t just about collecting information – it’s also about utilizing it effectively. Scanflow’s solutions don’t just provide raw data; they offer insights that can drive informed decision-making. By analyzing patterns, trends, and user behavior, businesses can make strategic choices that optimize processes, improve customer experiences, and drive growth.

A Sustainable Future for businesses

In conclusion, Scanflow’s data capture solutions are reshaping the way businesses operate. By leveraging advanced technology, these solutions unlock efficiency, accuracy, and insights that drive growth and innovation. From inventory management to healthcare and beyond, Scanflow empowers businesses to evolve, adapt, and succeed in an ever-changing landscape. As we move towards an increasingly digital future, Scanflow remains at the forefront of revolutionizing workflows for the better.