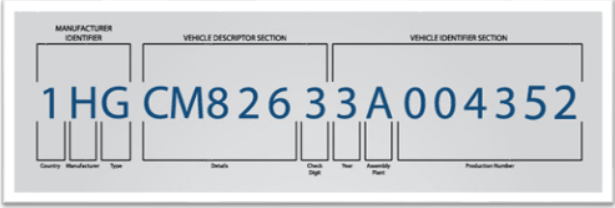

Scanflow specializes in intelligent text scanning and recognition of various types of data, including vehicle Identification numbers from smart devices.

While Scanflow can be utilized in various industries and applications, it can also be particularly useful in manufacturing industries for VIN (Vehicle Identification Number) scanning. Here’s how Scanflow can assist with

VIN number scanning in manufacturing:

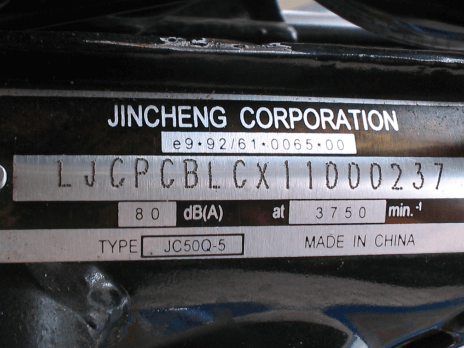

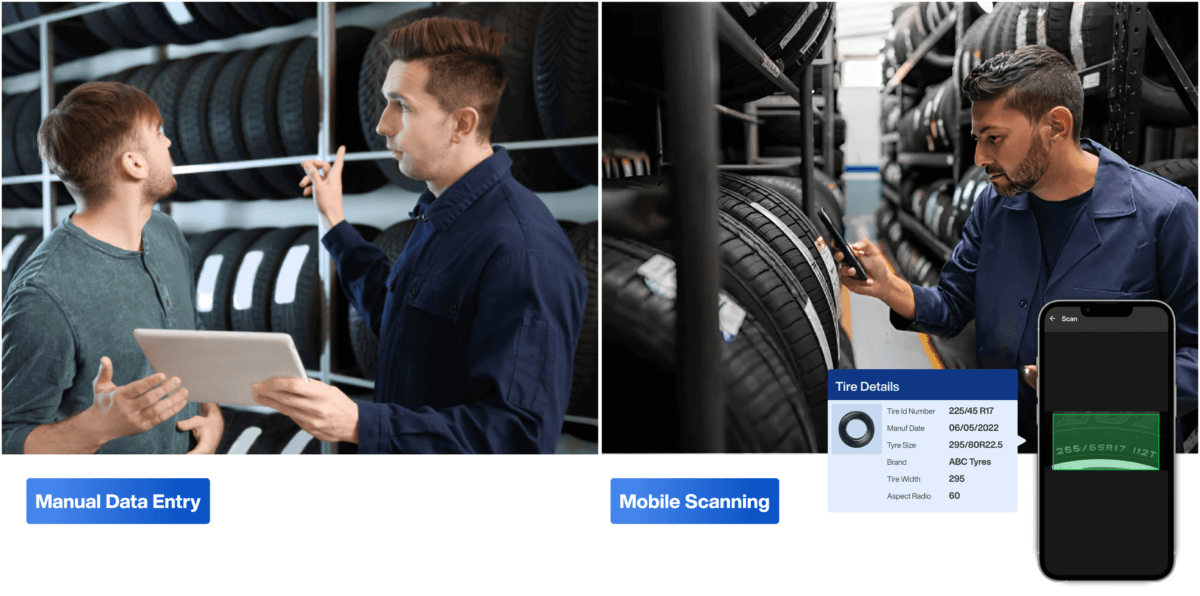

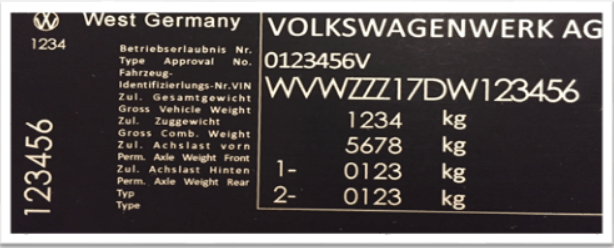

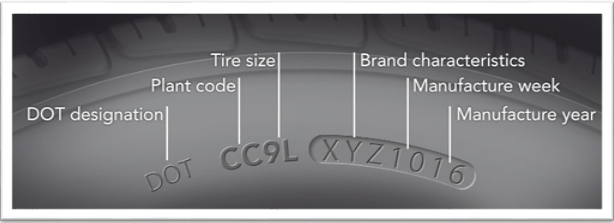

- Smart Scanning: Scanflow allows VIN numbers to be scanned directly from a vehicle’s VIN plate or label using a smart device. This scanning capability reduces the need for dedicated barcode scanners or manual data entry.

- Accuracy: Scanflow is designed to achieve high accuracy in reading VIN numbers, even in challenging lighting conditions or with imperfect VIN plates. It can recognize characters accurately by operating offline. This feature ensures that your workforce can reliably work with VINs wherever they are, even in remote or offline environments.

- Real-Time Data Capture: Scanflow provides real-time data capture capabilities, allowing manufacturing workers to quickly and accurately scan VINs without delays. This helps streamline manufacturing processes.

- Seamless Integration: Scanflow can be integrated into existing workflow applications or manufacturing systems. This integration ensures that scanned VIN data seamlessly flows into the manufacturing system for further processing and tracking.

- Quality Control: By scanning VINs during the manufacturing process, Scanflow helps verify that the correct VIN is associated with each vehicle. This is crucial for quality control and error prevention.

- Traceability: Scanned VIN data can be used to create a comprehensive record of each vehicle’s manufacturing history. This traceability is valuable for auditing, warranty tracking, and recall management.

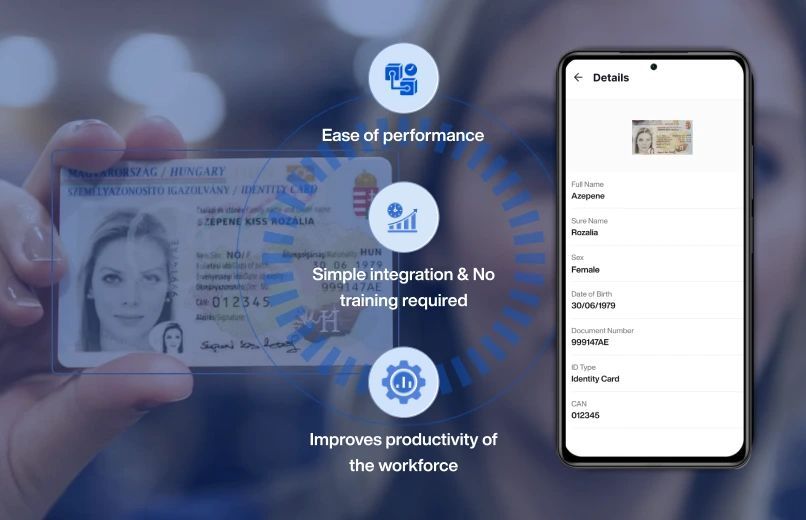

- User-Friendly Interface: Scanflow’s user-friendly interface makes it accessible to manufacturing personnel with minimal training. This ease of use promotes efficient adoption within manufacturing operations.

- Security: Scanflow ensures data security by processing and storing all scanned vehicle information offline. This means that sensitive VIN data remains protected and is not transmitted to third-party cloud servers, enhancing privacy and security.

- Flexibility: Scanflow VIN scanning technology is adaptable and versatile. It allows for scanning from a distance, even when dealing with dirty or partially obscured VINs. This flexibility ensures accurate data capture in real-world conditions, regardless of environmental challenges.

By integrating Scanflow for VIN number scanning, manufacturing industries can enhance efficiency, accuracy, and data integrity throughout the production process, ultimately leading to improved product quality and compliance with industry standards.