Introduction

Imagine a world where cracked VINs get scanned in a flash, paperwork melts away, and your dealership runs on autopilot. That’s the magic of Scanflow, the AI-powered sidekick that transforms your messy Vehicle Identification Number handling into a streamlined symphony. Ditch the typos, the delays, and the headaches. Scanflow’s smart scanners read even the most stubborn VINs, zap the data straight into your systems, and let you focus on what you do best: keeping customers happy and wheels turning. It’s like giving your dealership a superpower – the power of effortless VIN accuracy and efficiency. So, are you ready to say goodbye to manual error and hello to a smoother, smarter future with Scanflow.

VIN Challenges and Errors

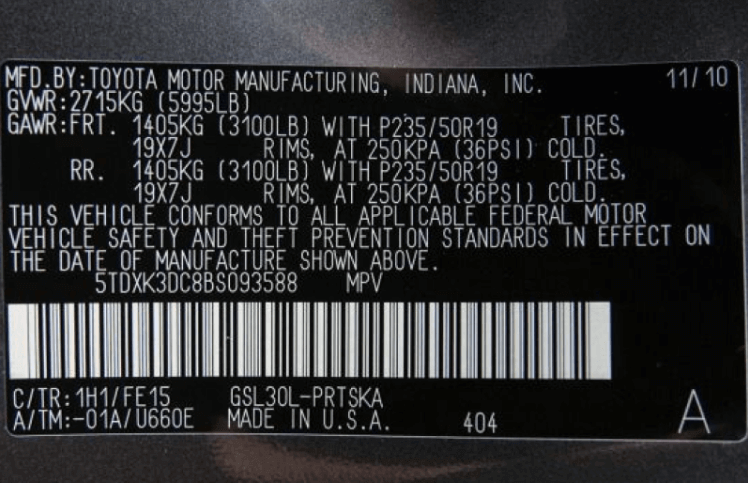

The vehicle VIN, a unique 17-character code, is like a secret key. It tells the whole story of the car, from where it came to who owns it now. But handling this code the old way, with pen and paper, can be a real mess.

Imagine a busy vehicle dealership, where workers scribble VINs on forms, their fingers hovering over keyboards, eyes squinting at faded numbers on sun-baked dashboards. It’s a recipe for mistakes! One tiny typo can mix up the whole car’s identity, leading to lost vehicles and angry customers.

These errors aren’t just annoying, they can be costly. A wrong number can mess up car counts, delay repairs, and even avoid warranties. And the worst part? It opens the door for fraud!

So, what’s the fix? Ditch the pen and paper and let machines do the work! Automated VIN scanners powered by AI can capture the code instantly and accurately, without any typos or squinting. This is the future of VIN handling, where mistakes are a thing of the past. The days of VIN-caused chaos are over, thanks to the magic of automation!

Unveiling the Scanflow Advantage

Say goodbye to the days of squinting at blurry VINs and battling typos! Scanflow unveils a revolutionary approach to VIN handling, powered by cutting-edge technology and AI smarts. Here’s how it redefines the game:

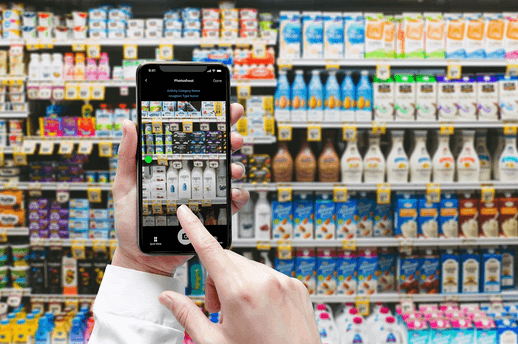

1. Seamless Capture: No more struggling with damaged or obscured VINs. Scanflow’s advanced scanners boast lightning-fast reading, even on scratched, faded, or partially covered codes. Whether it’s baked under the hood or hiding in a dark corner, Scanflow captures it all, instantly and accurately.

2. Data Integration: Forget the manual data entry dance. Scanflow seamlessly integrates with your existing dealership workflows. The captured VIN data is instantly zapped into your systems, automatically updating records, creating service orders, and streamlining every step of the process. No more double-entry purgatory, just smooth, real-time data flow.

3. Automated Tasks: Ditch the paper forms and repetitive keystrokes. Scanflow automates tedious tasks like VIN verification and data entry. This frees up your staff to focus on what truly matters: delivering exceptional customer service, attending to repairs, and ensuring smooth operations. Every minute saved is a minute earned for your dealership’s success.

Scanflow isn’t just about speed and accuracy; it’s about empowering your dealership to operate at peak efficiency. By eliminating manual errors, streamlining workflows, and freeing up valuable time, Scanflow unlocks a world of possibilities. Imagine a dealership where VINs are a breeze, paperwork melts away, and your staff can focus on what they do best – making your customers happy and keeping your business thriving. That’s the power of Scanflow, the AI-powered solution that transforms VIN handling from a chore to a seamless superpower.