In the dynamic realm of warehouse management, accuracy, precision and operational efficiency stand as the cornerstones of success. To remain at the forefront of the field, a complete transformation of their tire stock management workflow was essential. Thus began their ambitious endeavor to modernize operations, harnessing cutting-edge technologies and innovative methodologies.

A large tire manufacturing warehouse faced a multitude of challenges that hampered their tire stock management. Some of their everyday workflow challenges were,

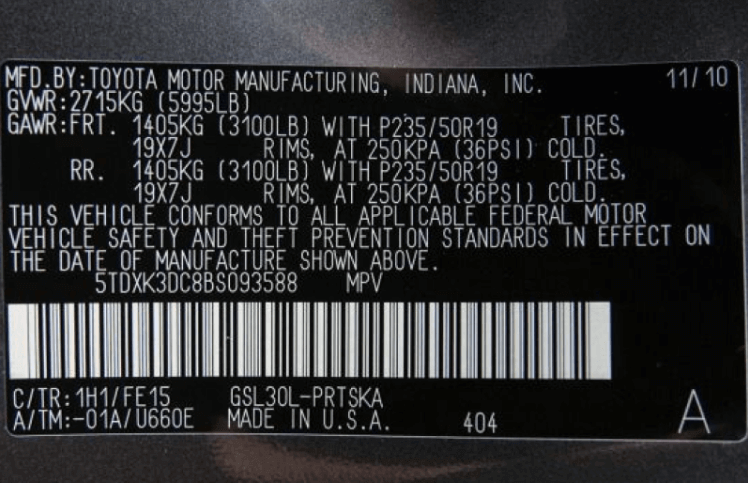

Data Accuracy: Maintaining precise tire identification and record-keeping can be challenging, especially when dealing with a large inventory. Tire identification must be accurate to prevent errors in inventory tracking. Errors in data entry or loss of information can lead to inventory discrepancies and operational inefficiencies.

Aging Goods Identification: Identifying aging goods is essential to prevent wastage. Tires have a limited shelf life, and if older tires are not identified and used or disposed of properly, it can result in financial losses. Effectively tagging older goods based on the threshold frequency criterion to prevent wastage.

Document Management: Tire inventories often require accompanying documents, such as purchase orders, invoices, and quality reports. Managing and linking these documents to specific tires is essential for traceability and compliance. This can be a cumbersome task if not automated.

Inaccurate tracking during these crucial stages can lead to understock or overstock situations, which can affect production schedules and customer orders. Ensuring accurate inventory updates during loading and unloading is crucial

Data Synchronization: This challenge involves integrating multiple data sources and systems. Achieving seamless synchronization is essential to match the physical location and status of tires with the data in the inventory management system. Integrating multiple systems with inventory management can be complex and costly.

System Integration Complexity: Integrating backend systems like SAP to streamline data updates and reduce manual efforts. It often requires custom development to ensure data flows smoothly between systems.

Data Security: Safeguarding sensitive information captured during scanning and documentation. Tire data often includes proprietary designs, manufacturing processes, and customer information. Ensuring that this data is secure from unauthorized access or breaches is a significant challenge, especially in an interconnected environment.

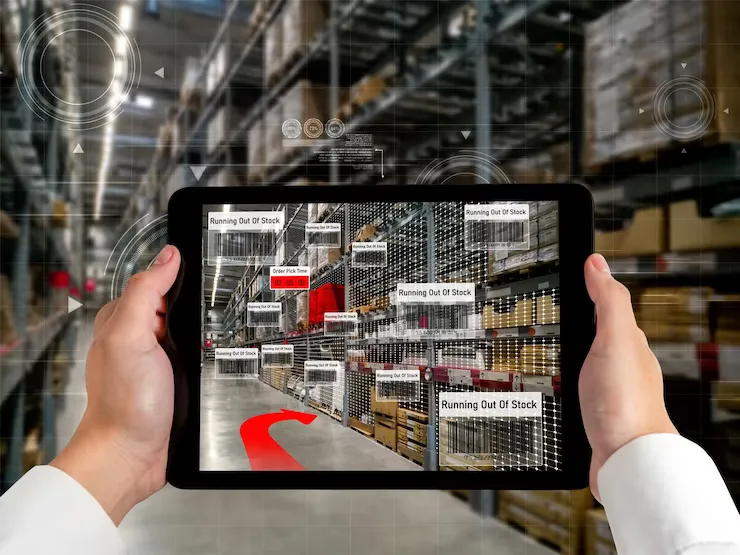

To address these challenges comprehensively, the warehouse devised a strategic plan with Scanflow,

They developed an integrated solution with Scanflow that revolutionized tire stock management which encompassed every facet of their operations.

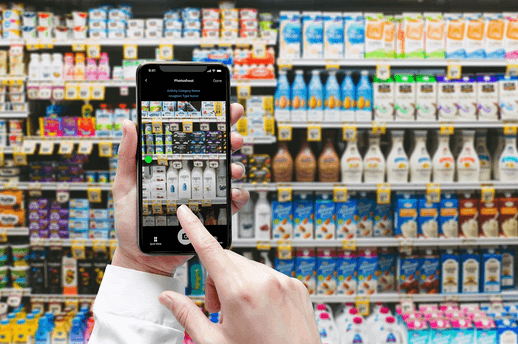

Scanflow automates the workflow process by enhancing the key processes like serial scanning, tagging, document comparison, and data synchronization were automated. This not only reduced errors but also saved valuable time. Vision Intelligence was deployed to identify color or year information, enhancing the accuracy of tire identification. System integration with SAP streamlined backend updates. With Scanflow real-time data accuracy became the norm across all stages of tire management, from inventory creation to loading and unloading. Manual steps were minimized, and overall efficiency improved significantly.

The Result

Improved Inventory Management: The Warehouse achieved impeccable control over their tire stock, eliminating discrepancies and inefficiencies. Regular inventory audits and cycle counts were conducted to eliminate discrepancies between recorded and actual stock levels. Inefficiencies, such as overstocking or understocking, were identified and rectified, ensuring that the right tires were available when needed.

Cost Savings: By preventing wastage and optimizing operations, significant cost savings were realized. Efficient operations and accurate inventory data also led to reduced labor costs and minimized the need for emergency orders. Lowering operational costs and reducing waste contributed to significant overall cost savings.

Customer Satisfaction: Accurate and on-time deliveries improved customer satisfaction, cementing the warehouse’s reputation as a reliable supplier. Meeting delivery promises builds trust with customers, and high customer satisfaction often leads to repeat business and positive referrals. This heightened level of service cements the warehouse’s reputation as a reliable supplier in the tire industry.

Competitive Edge: The state-of-the-art tire warehouse management system gave the Warehouse a distinct competitive advantage. These advanced capabilities would give the warehouse a distinct advantage over competitors who might still be relying on manual or outdated systems.

Scalability: This could involve features like flexible storage solutions, the ability to add new locations or expand existing ones and handling increased order volumes without major disruptions. Scalability ensures the warehouse can adapt to market fluctuations and increased demand without sacrificing efficiency or accuracy.

The tire manufacturing warehouse management integrated with Scanflow showcases the remarkable potential of embracing modern technologies and innovative practices in traditional industries. By addressing pain points and challenges head-on and aligning their objectives with specific focus areas, the warehouse not only optimized their processes but also improved accuracy, efficiency, and overall operations. This transformation not only propelled them to the forefront of their industry but also inspired others to follow suit, marking a significant milestone in the world of warehouse management.

Read more on tire sidewall scanning: Tire Sidewall Scanning | Tire Scanner SDK | Scan TIN, DOT Codes and Tire Sizes – ScanFlow