Quality control is a fundamental part of modern production, not a post-process task. As product lines become more complex and output volume increases, manual inspection methods are falling behind. Inconsistencies, sampling limitations, and human fatigue reduce reliability, and in many industries, the cost of missing a defect can far outweigh the cost of detection.

Automated visual inspection using AI offers an operational alternative. These systems continuously monitor parts, packaging, and assemblies to identify non-conformities in real time. Unlike human-led visual checks, they work consistently at production speed and are not limited by field of view or repetition.

Here are five industries where AI quality control is not just helpful but critical for managing cost, safety, and operational flow.

1.Automotive Manufacturing

What’s at Risk?

In automotive production, even a minor undetected fault can cause downstream failures, recalls, or safety risks. As vehicles become more modular and software-controlled, part accuracy and fitment consistency are critical.

Where AI Quality Control Fits

- Identifies missing or misaligned parts during sub-assembly

- Validates correct placement of components in high-speed conveyor lines

- Checks paint variation, fastener placement, and body alignment at multiple checkpoints

Automated inspection removes dependency on sampling and enables every part to be checked in line. This lowers rework, prevents shipment of defective components, and supports consistent assembly logic across models.

2.Electronics and PCB Assembly

What’s at Risk?

Electronics manufacturing deals with micro components, layered boards, and solder joints. Errors can lead to immediate product failure or degraded performance over time. Manual checks are often insufficient for dense assemblies and repeated inspection tasks.

Where AI Quality Control Fits

- Scans PCB surfaces to verify component position and orientation

- Detects solder joint quality and solder bridge formation

- Identifies missing, rotated, or offset elements

Automated systems offer consistent board-level checks at the speed of production. They also reduce reliance on microscope-based checks and help log inspection outcomes across batches.

3.FMCG and Consumer Goods

What’s at Risk?

In fast-moving consumer goods, inconsistent packaging, labeling issues, or contamination can lead to rejected batches and brand damage. Human inspection during high-speed production often misses subtle or recurring defects.

Where AI Quality Control Fits

- Confirms cap placement, seal presence, and fill level in bottling and packaging

- Verifies label orientation, print quality, and product completeness

- Detects mold defects, foreign particles, or missing items in packaged kits

Visual inspection systems work continuously across shifts, detecting recurring packaging issues without slowing output. This supports error-free delivery and reduces quality-based returns or retailer rejections.

4.Pharmaceutical Manufacturing

What’s at Risk?

Pharmaceutical packaging and labeling must comply with strict regulations. Errors can lead to rejected shipments, non-compliance penalties, or in extreme cases, health risks to patients.

Where AI Quality Control Fits

- Verifies printed content on labels such as batch codes and expiration dates

- Checks blister pack alignment, completeness, and sealing

- Detects leaflet presence, carton folding accuracy, and box orientation

These checks are conducted without manual intervention and can be scaled to suit both static packaging stations and fast conveyor lines. Data from inspections can also support documentation required for regulatory audits.

5.Metal and Steel Processing

What’s at Risk?

In metal processing, dimensional accuracy and surface consistency are essential. Surface-level flaws and forming inconsistencies may not be visible until much later in the process, making early detection valuable.

Where AI Quality Control Fits

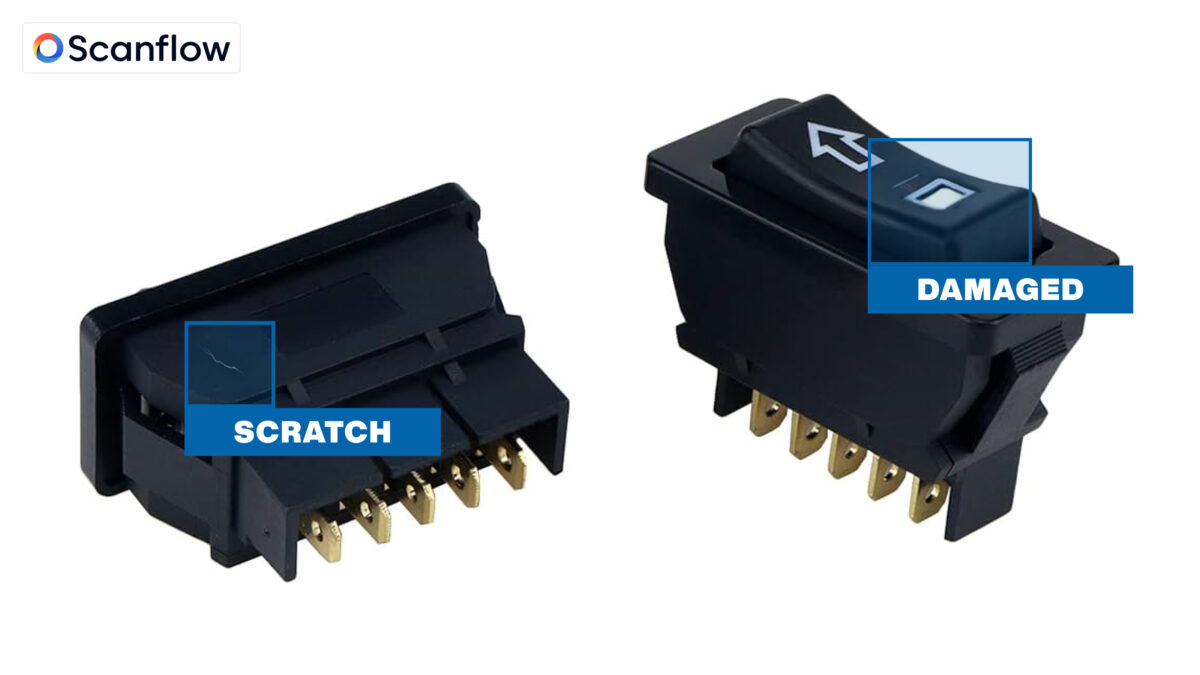

- Identifies surface defects such as cracks or incomplete finishes

- Monitors part shape and size during cutting or machining

- Detects process deviation during rolling or extrusion

AI inspection systems installed at forming or finishing points help reduce scrap, minimize second-pass processing, and ensure that specifications are met before moving parts forward for final use.

Why Manual Inspection No Longer Scales

Across all five industries, manual visual checks present common limitations:

- Inspection fatigue across long shifts

- Inconsistent results across operators

- Limited coverage (sampling vs. full unit inspection)

- Delayed defect detection after the next process step

AI visual inspection helps resolve these by introducing structured, programmable checkpoints. The system can be trained to detect specific non-conformities, linked to plant logic, and deployed without disrupting upstream or downstream flow.

Adoption Model: Where AI Quality Control Typically Starts

Most manufacturers begin by deploying AI quality control at one of three stages:

- Conveyor-based inspection during active production to identify defects in motion

- Static inspection stations for verifying critical components between process phases

- End-of-line inspection to confirm completeness before packaging or shipment

These systems work with standard cameras, smart devices, or edge-mounted infrastructure and integrate with MES or quality management software for centralized visibility.

Conclusion

The shift toward structured, automated inspection is not driven by convenience but by operational need. Missed defects create bottlenecks, safety concerns, and cost overhead that manual systems struggle to contain.

Scanflow’s AI quality control platform enables production teams to run real-time inspections without changing their existing infrastructure. Whether deployed inline, at dedicated visual checkpoints, or at dispatch gates, it supports fast, reliable inspection to help ensure product consistency and reduce downstream risk.

Looking to evaluate AI quality control for your operations?

Request a Demo now to see how Scanflow can help your business scale!