Construction sites are dynamic and potentially hazardous environments where the safety of workers is paramount. Ensuring that all personnel are equipped with necessary personal protective equipment (PPE), such as helmets, vests, and gloves, is critical in preventing accidents and injuries. Traditional methods of monitoring PPE compliance can be labor-intensive and error prone. However, the advent of automated PPE detection technology offers a robust solution. This article explores the application of an automated PPE detection and alert system in construction sites, detailing its functionality, benefits, and impact on safety management.

How the Automated PPE Detection System Works

Imagine a busy construction site where dozens of workers are engaged in various tasks, from building scaffolds to operating heavy machinery. Safety is a top priority, but manually monitoring each worker to ensure they are wearing the necessary personal protective equipment (PPE) can be challenging. This is where the automated PPE detection system comes into play, ensuring compliance and enhancing safety through advanced technology. The automated PPE detection system uses advanced computer vision and machine learning algorithms to monitor workers in real-time and ensure compliance with PPE requirements. Here’s how the system operates:

- CCTV Monitoring: Early in the morning, the construction site comes alive with construction activity. High-resolution CCTV cameras are strategically installed at key locations such as entry points, work zones, machinery areas, and begin capturing video footage. These cameras are positioned to cover all angles, ensuring that no area is left unmonitored and capture clear and detailed images. These images provide the raw data that the system needs to analyze and detect PPE compliance accurately.

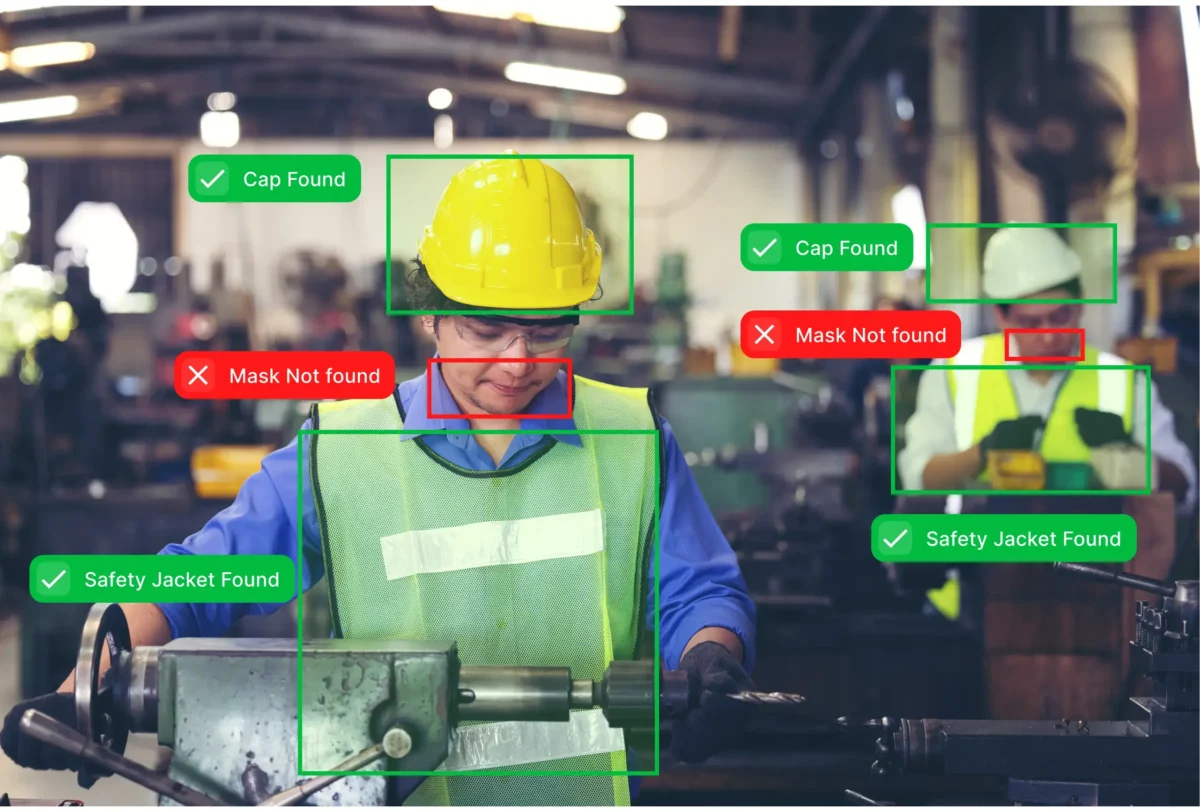

- PPE Detection: As workers move about the site, the video feed from the cameras is continuously streamed to a central processing unit. The system uses advanced computer vision algorithms, trained on thousands of images, to identify specific items of PPE, such as helmets, vests, and gloves. For instance, as a group of workers begins to install steel beams, the system scans each individual to confirm they are wearing their helmets, reflective vests, and gloves.

The computer vision algorithms are designed to recognize the shapes, colors, and textures of the required PPE. By comparing the real-time video feed with its trained dataset, the system can accurately detect whether each worker is wearing the necessary safety gear. This detection happens in real-time, allowing for immediate identification of compliance or non-compliance. - Violation Detection: When the system identifies a worker who is not wearing a helmet and busy with a task, has removed the helmet momentarily. The system immediately flags this as a violation. A marker is placed on the live video feed, highlighting the non-compliant worker. When a worker is detected without the necessary PPE, the system flags this as a violation.

The system’s ability to detect violations relies on its continuous analysis of the video feed. When it spots a worker without the required PPE, it uses a combination of object recognition and motion tracking to ensure that the violation is accurately identified and recorded. This process ensures that even momentary lapses in PPE use are detected. - Real-Time Alert: As soon as the violation is detected, an audible alert sounds on the consol of the construction site. This alert is designed to be loud enough to be heard. The worker and nearby colleagues hear the alert and immediately recognize that there is a safety issue.

The real-time alert serves as an immediate call to action. The sound draws attention to the non-compliance, prompting the worker to correct the issue promptly. This instant feedback mechanism ensures that safety violations are addressed on the spot, minimizing the risk of accidents. - Notify the Site Owner: Concurrently, the system sends a notification to the site owner’s through WhatsApp. The message includes critical information about the violation: the time it occurred, the exact location, and a snapshot from the video footage showing the worker without the helmet. The site owner, who may be off-site, receives this information in real-time and can review the incident.

By sending detailed messages to the site owner, the system ensures that top-level management is always aware of the site’s safety status. This transparency allows for better oversight and ensures that safety protocols are enforced consistently. The snapshot from the video footage provides visual evidence of the violation, making it easier to address and document the issue.

Benefits of the Automated PPE Detection and Alert System

- Enhanced Safety: The primary benefit of the automated PPE detection and alert system is the significant enhancement of safety on construction sites. By providing continuous and automated monitoring, the system ensures high levels of PPE compliance among workers. This constant vigilance reduces the likelihood of accidents and injuries, as workers are more likely to adhere to safety protocols when they know they are being monitored. The immediate detection and correction of PPE violations prevent potentially hazardous situations from escalating, thereby creating a safer working environment for everyone involved.

- Operational Efficiency: The system greatly improves operational efficiency by automating the monitoring process. Traditional methods of ensuring PPE compliance often require dedicated safety officers to conduct regular inspections and checks, which can be time-consuming and labor-intensive. With the automated system in place, these manual checks are significantly reduced, allowing safety officers to focus on other critical tasks such as safety training, hazard assessment, and emergency preparedness. This shift not only optimizes the use of human resources but also ensures that the site operates smoothly and efficiently.

- Immediate Corrective Actions: One of the key advantages of the automated PPE detection system is its ability to facilitate immediate corrective actions. When a PPE violation is detected, the system generates real-time alerts, which can be in the form of audible alarms on-site, push notifications to supervisors’ mobile devices, or visual cues on the live video feed. These instant alerts prompt immediate responses, ensuring that non-compliance is addressed quickly and effectively. This rapid response capability is crucial in mitigating risks and preventing accidents, as it minimizes the time workers are exposed to potential hazards.

- Accountability and Transparency: The automated system enhances accountability and transparency within the construction site. Every compliance incident is logged with detailed information, including the time, location, and a snapshot from the video footage. These logs provide a clear record of all safety breaches and the actions taken to address them. This comprehensive documentation is invaluable for safety audits, as it offers concrete evidence of compliance efforts and incident responses. Moreover, the data collected can be analyzed to identify recurring issues and areas for improvement, informing targeted safety training and policy adjustments.

- Regulatory Compliance: Adhering to safety regulations is a critical aspect of construction management, and the automated PPE detection system plays a vital role in ensuring regulatory compliance. The system’s detailed logging and reporting capabilities help construction companies maintain accurate records of PPE compliance, which is essential during regulatory inspections and audits. By consistently monitoring and documenting PPE use, the system minimizes the risk of penalties and legal issues associated with non-compliance. Furthermore, the detailed reports generated by the system provide insights that can be used to improve safety practices, ensuring that the site not only meets but exceeds regulatory standards.

The automated PPE detection and alert system revolutionizes construction site safety by ensuring real-time monitoring and compliance. It significantly enhances worker protection, boosts operational efficiency, and ensures regulatory adherence. This proactive approach not only safeguards workers but also fosters a culture of accountability and continuous improvement. By integrating advanced technology, construction companies can create safer, more efficient environments, ultimately leading to fewer accidents and higher productivity.