Executive Summary

In 2025, U.S. tire recyclers face tightening state and federal compliance requirements for waste tire transportation, storage, and recycling documentation. Manual recordkeeping and paper manifests are no longer sufficient to meet evolving mandates from agencies such as CalRecycle (California), TCEQ (Texas), and the EPA.

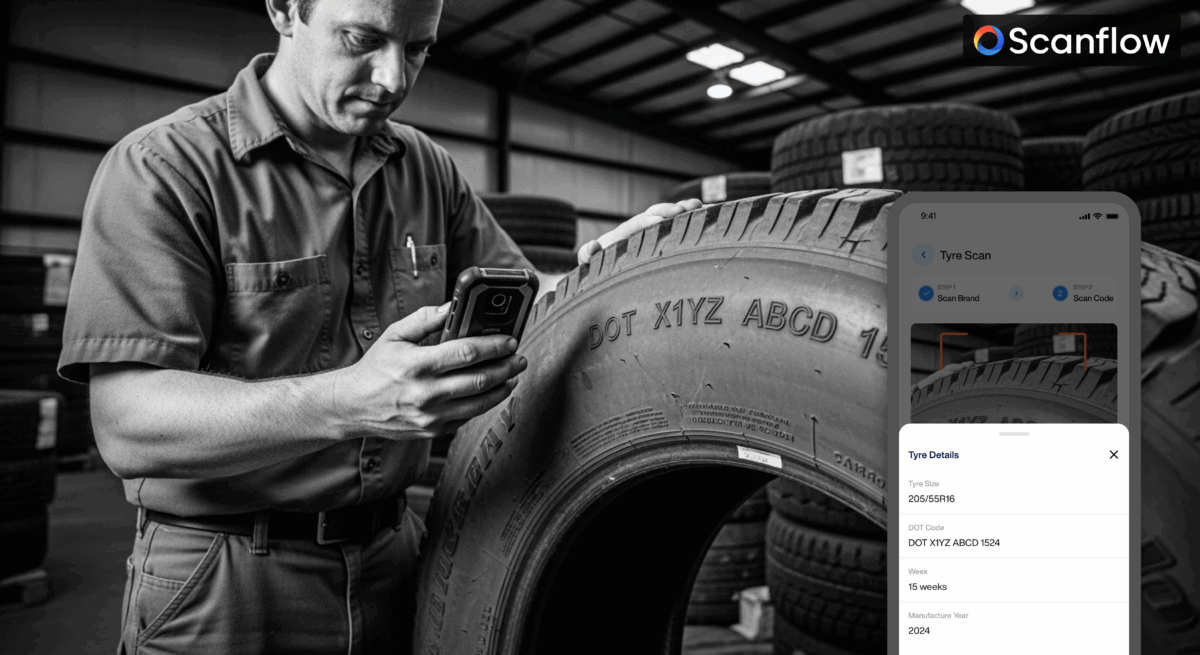

To stay compliant and profitable, tire recyclers are turning to AI-powered scrap tire scanning that automates tire identification, helps with manifest preparation and reporting. These solutions deliver real-time data accuracy, audit-ready documentation, and end-to-end visibility reducing compliance costs and eliminating the risk of fines.

By leveraging AI, recycling facilities can digitize their compliance workflows, streamline manifests, and ensure consistent reporting accuracy, while maintaining data privacy and operational efficiency. Human oversight remains essential for interpreting context and validating data integrity, ensuring that automation supports not replaces regulatory accountability.

The 2025 Compliance Landscape for Tire Recyclers

State and Federal Oversight Intensifies

- CalRecycle mandates hauler registration, manifests for loads of 10+ tires, and electronic trip logs for waste tracking.

- TCEQ (Texas) enforces annual reporting and digital manifesting under its Scrap Tire Program.

- Colorado’s 6 CCR 1007-2 regulation requires manifests and 3-year record retention for all generators and recyclers.

- EPA sustainability frameworks are pushing for digital waste tracking systems across multiple industries by 2025.

Key Compliance Risks

- Missing or incomplete tire manifests.

- Incorrect or unreadable DOT codes on sidewalls.

- Inconsistent reporting between transporters and processors.

- Lost paper documentation during audits.

Fines can reach $25,000 per violation with additional penalties for repeat offenders.

AI-Powered Compliance: The New Standard

AI is transforming compliance from a reactive reporting task into a proactive, automated process.

Automated Tire Identification

- AI tire sidewall scanners capture DOT codes, brands, and serial details in real time.

- Visual intelligence models identify sidewalls even under dirt, damage, or low light.

- Each scan produces structured, tamper-proof digital data ready for audit review.

Manifest Generation and Reporting

- AI solutions like Scanflow compile captured data into complete digital manifests, automatically linking:

- Source and destination facilities.

- Transporter identification and load IDs.

- Timestamped scan logs and batch summaries.

- Helps create manifests that align with CalRecycle’s CTL and TCEQ reporting templates, minimizing administrative overhead.

Predictive Compliance Monitoring

- AI flags missing tire counts, duplicate records, and data anomalies before audits.

- Dashboards track real-time compliance performance, providing alerts for immediate correction.

Operational Transformation with AI Tire Scanning

Speed, Scale, and Precision

AI scanning enables tire processors to access huge volumes of tires, integrating seamlessly into existing systems.

- Continuous scanning ensures uninterrupted workflow.

- Batch-level reporting aggregates data for bulk shipments.

- Local (on-device) processing ensures immediate feedback and no internet dependency.

- All data is processed locally for full offline capability.

- Meets EPA, GDPR, and state-level data privacy standards.

Business Impact: Turning Compliance into Competitive Advantage

AI tire scanning isn’t just about avoiding fines it’s a strategic investment in efficiency and growth.

| Outcome | AI-Driven Impact |

|---|---|

| Faster Operations | 60–70% increase in throughput via automation. |

| Fewer Errors | 80% reduction in data discrepancies and reporting mistakes. |

| Improved Audit Readiness | Instant manifest retrieval and clean digital records. |

By embedding AI into daily recycling operations, companies gain a long term edge in both compliance reliability and operational agility.

Optimizing Compliance Workflows with Scanflow

Scanflow’s Tire Sidewall Scanner helps recyclers implement digital compliance seamlessly through:

- Hardware Integration: AI tire sidewall scanners retrofit easily into systems and inspection lines.

- Data Dashboards: Real-time monitoring of tire inventory, shipment progress, and manifest status.

- Reporting: Export-ready files compatible with CalRecycle, TCEQ, and EPA databases.

- Predictive Insights: Early warnings for potential non-compliance issues.

This makes compliance visible, measurable, and verifiable turning regulatory obligations into process efficiency.

Practical Benefits for Tire Recyclers

- Faster Audit Response: Generate digital manifests in seconds; auditors get clean, timestamped data instantly.

- Lower Administrative Overhead: Reduce manual documentation and repetitive data entry, freeing staff for higher-value tasks.

- Scalable and Flexible: Works across multi-site operations, from regional haulers to national recycling networks.

- Real-Time Compliance Assurance: Get notified the moment a record goes missing or a data mismatch occurs.

Conclusion: The Future of Tire Recycling Compliance

AI is redefining how compliance is achieved, managed, and measured. By integrating tire sidewall scanning and automated manifest generation, recyclers can eliminate manual errors, reduce risk, and build transparency across their operations.

In 2025, compliance isn’t just about meeting regulations it’s about leading with precision, trust, and innovation. Scanflow enables recyclers to do exactly that.

Book a Demo with Scanflow

Regulatory compliance doesn’t have to slow your business down. With Scanflow, you can automate compliance tracking, manifest creation, and audit reporting all in real time.