Why Traceability is Key for Tyre Movement Between Warehouses and Retailers

Introduction The automotive tyre industry moves millions of units each year across warehouses, reta...

3 Mins read

Posted on Aug 21, 2025

June 19, 2025

3 Mins read

Pharmaceutical companies today face real problems with manual tracking systems that just don’t cut it anymore. Workers spend hours manually entering batch numbers, checking labels, and verifying products all while dealing with tight deadlines and zero tolerance for mistakes. One wrong batch number can trigger a costly recall. Scanflow’s asset identification SDK changes this completely by using AI mobile scanning to read and verify product information straight from the packaging, making pharma distribution operations faster and more reliable.

How Scanflow Transforms Pharma Operations

1. Batch Number Capture

Manual batch tracking is where most pharma operations lose time and money. Workers squint at tiny printed numbers, type them into systems, and hope they got it right. With thousands of products moving through facilities daily, human error is inevitable.

Scanflow’s system reads batch numbers directly from packages using AI technology. It achieves 98% accuracy rates, which beats manual entry by a wide margin. The system works even when batch numbers are printed on difficult surfaces like curved bottles or glossy labels. No more transcription errors, no more having to double-check every entry, and no more recalls caused by tracking mistakes.

2. Real-Time Inventory Control

Most pharma distribution centers still rely on outdated tracking methods that update inventory hours or even days after products move. This creates blind spots where nobody knows exactly what’s in stock or where specific batches are located.

Scanflow optimizes asset tracking and inventory management, automating barcode processing and improving in pharma distribution and warehouses. The asset identification solution provides real-time visibility into pharmaceutical inventory levels, locations, and movement throughout the pharma distribution supply chain. When products move, the system updates immediately. Integration with existing WMS and ERP systems means inventory records stay current without extra work from warehouse staff.

3. Complete Label Verification in One Scan

Current label checking processes require workers to manually verify multiple data points – expiration dates, lot numbers, NDC codes, dosage information. This takes time and creates opportunities for oversight, especially during busy periods.

Scanflow’s system reads and validates different data fields from pharmaceutical labels in a single scan. This eliminates the tedious manual checking process while ensuring every package meets specifications.

4. Faster Operations With Better Accuracy

Traditional pick and pack operations in pharmaceutical facilities and pharma distribution centers often involve time consuming manual verification processes. Scanflow’s asset identification solution improves operational efficiency by automating multiple verification steps simultaneously. Workers can scan, verify, and process products 70% faster than manual methods.

The system handles product codes, batch numbers, expiration dates, and quality checks all at once. This speed increase means facilities can process more orders per day without adding staff. Workers focus on handling products and solving problems instead of data entry and verification tasks.

5. Complete Product Traceability from Start to Finish

Tracking products through the entire supply chain is mandatory in pharma, but most companies struggle with gaps in their traceability records. When regulators ask for complete product history or when recalls happen, teams scramble to piece together information from multiple systems and paper records.

Scanflow creates an unbroken chain of custody for every product that passes through your facility. Every scan captures location, timestamp, operator ID, and product details automatically. The system tracks products from receiving through storage, picking, packing, and shipping without requiring extra data entry from workers.

When you need traceability information whether for a routine audit, customer inquiry, or recall situation – everything is already documented and searchable. The system shows exactly where each batch has been, who handled it, and when each step occurred. This complete visibility helps companies respond faster to regulatory requests and reduces the time spent investigating product history issues.

Scanflow’s Mobile SDK Technology

Scanflow’s asset identification solution is built on a mobile SDK that works with existing pharmaceutical operations. The platform uses computer vision algorithms trained specifically for pharmaceutical packaging, handling different box sizes, label formats, and printing styles commonly found in pharma distribution.

The scanning technology adapts to various lighting conditions and package orientations that occur in real warehouse environments. The AI learns from each facility’s specific products and improves recognition over time. The mobile SDK works on handheld devices, tablets, and fixed scanning stations, giving companies flexibility in how they deploy the technology.

Business Impact and Measurable Results

Companies using Scanflow’s asset identification solution see results within months of implementation. Labor costs drop significantly when workers stop spending time on manual data entry. Error rates decrease, which means fewer returns, recalls, and compliance issues. Processing speed increases allow facilities to handle more volume without expanding staff.

The system scales across multiple facilities and product lines as companies grow. The technology integrates with existing warehouse management systems without disrupting current workflows. For pharmaceutical operations dealing with increasing volume and tighter regulations, automated asset identification isn’t just helpful it’s becoming necessary for staying competitive.

Why Traceability is Key for Tyre Movement Between Warehouses and Retailers

3 Mins read

Posted on Aug 21, 2025

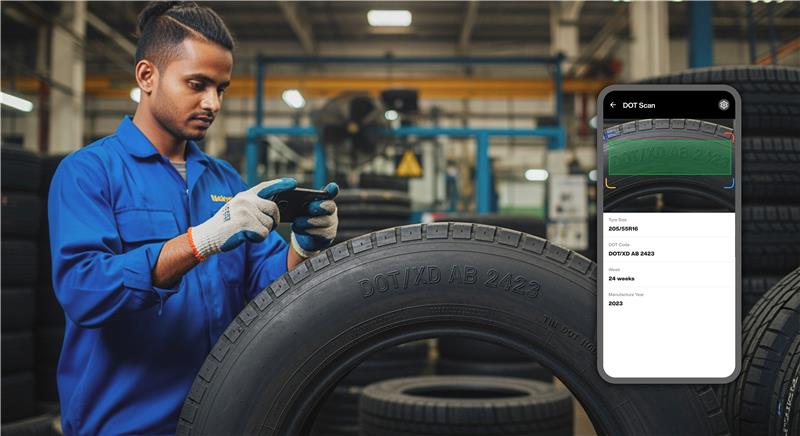

How AI Scanner Help Capture TIN and DOT Numbers to Enable Smarter Tire Tracking

2 Mins read

Posted on Jul 2, 2025

This privacy policy sets out how Scanflow uses and protects any information that you give Scanflow when you use this website. Scanflow is committed to ensuring that your privacy is protected. We shall ask you to provide certain information by which you can be identified when using this website, then you can be assured that it will only be used in accordance with this privacy statement.

Scanflow may change this policy from time to time by updating this page. You should check this page from time to time to ensure that you are happy with any changes.

What We Collect

We may collect the following information:

Name and job title

Contact information including email address

Demographic information such as postcode, preferences and interests

Other information relevant to customer surveys and/or offers

What we do with the information we gather

We require this information to understand your needs and provide you with a better service, and in particular for the following reasons:

Internal record keeping.

We may use the information to improve our products and services.

We may periodically send promotional emails about new products, special offers or other information which we think you may find interesting using the email address which you have provided.

From time to time, we may also use your information to contact you for market research purposes. We may contact you by email, phone, fax or mail.

We may use the information to customize the website according to your interests.

Security

We are committed to ensuring that your information is secure. In order to prevent unauthorized access or disclosure, we have put in place suitable physical, electronic and managerial procedures to safeguard and secure the information we collect online.

How we use cookies

A cookie is a small file which asks permission to be placed on your computer’s hard drive. Once you agree, the file is added and the cookie helps analyze web traffic or lets you know when you visit a particular site. Cookies allow web applications to respond to you as an individual. The web application can tailor its operations to your needs, likes and dislikes by gathering and remembering information about your preferences.

We use traffic log cookies to identify which pages are being used. This helps us analyze data about webpage traffic and improve our website in order to tailor it to customer needs. We only use this information for statistical analysis purposes and then the data is removed from the system.

Overall, cookies help us provide you with a better website, by enabling us to monitor which pages you find useful and which you do not. A cookie in no way gives us access to your computer or any information about you, other than the data you choose to share with us.

You can choose to accept or decline cookies. Most web browsers automatically accept cookies, but you can usually modify your browser setting to decline cookies if you prefer. This may prevent you from taking full advantage of the website.

Links to other websites

Our website may contain links to other websites of interest. However, once you have used these links to leave our site, you should note that we do not have any control over that other website. Therefore, we cannot be responsible for the protection and privacy of any information which you provide whilst visiting such sites and such sites are not governed by this privacy statement. You should exercise caution and look at the privacy statement applicable to the website in question.

Controlling your personal information

You may choose to restrict the collection or use of your personal information in the following ways:

Whenever you are asked to fill in a form on the website, look for the box that you can click to indicate that you do not want the information to be used by anybody for direct marketing purposes

If you have previously agreed to us using your personal information for direct marketing purposes, you may change your mind at any time by writing to or emailing us at info@scanflow.ai We will not sell, distribute or lease your personal information to third parties unless we have your permission or are required by law to do so. We may use your personal information to send you promotional information about third parties which we think you may find interesting if you tell us that you wish this to happen. If you believe that any information, we are holding out from you is incorrect or incomplete, please write to or email us as soon as possible at the above address. We will promptly correct any information found to be incorrect.